FRP trench covers outperform traditional materials by combining strength, lightweight design, and superior resistance to harsh environments. They help reduce installation costs, maintenance efforts, and safety hazards, making them the perfect long-term investment for various industries.

Material:

FRPApplication:

RooftopColor:

Yellow, Green, Gray, Blue ......Width:

300mm/400mm/450mm /anyother sizeHeight:

20/25/30......Length:

As per your request.Overview

Fiberglass Trench Covers, also known as FRP (Fiber Reinforced Plastic) Trench Covers, are high-performance alternatives to traditional metal and concrete trench covers. Engineered for superior strength, corrosion resistance, and ease of handling, these covers provide a cost-effective and long-lasting solution for various industrial, commercial, and public infrastructure applications. Their lightweight yet high load-bearing capacity makes them an ideal choice for areas requiring durable and maintenance-free trench protection.

| Legend |

Specification (mm) |

Mesh Size (mm) |

Thickness (mm) |

Bar Thickness (mm) |

Full Panel Size (mm) |

Weight (kg/㎡)

|

Open Rate (%) |

|

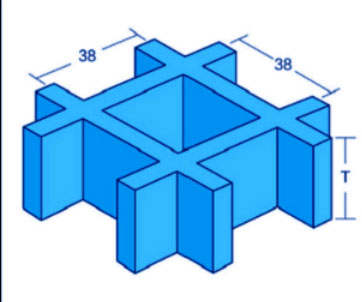

38*38*15 | 38*38 | 15 | 6.0/5.0 |

1220*3660 1260*3660 |

7.0 | 75 |

| 38*38*25 | 38*38 | 25 | 6.5/5.0 |

1220*3660 1220*2440 |

12.3 | 68 | |

| 38*38*30 | 38*38 | 30 | 6.5/5.0 |

1220*3660 1220*4040 |

14.6 | 68 | |

| 38*38*38 | 38*38 | 38 | 7.0/5.0 |

1220*3660 1000*4040 |

19.5 | 65 | |

|

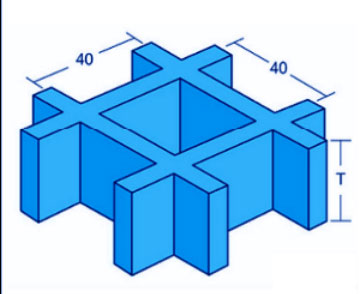

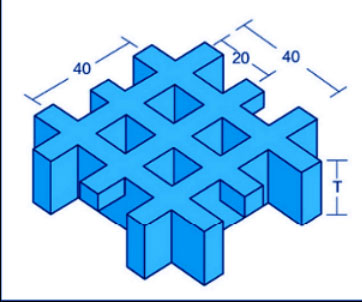

40*40*25 | 40*40 | 25 | 7.0/5.0 |

1007*3007 |

12.3 | 67 |

| 40*40*30 | 40*40 | 30 | 7.0/5.0 |

1007*3007 |

14.6 | 67 | |

| 40*40*40 | 40*40 | 40 | 7.0/5.0 |

1247*3687 1007*3007 |

19.5 | 67 | |

|

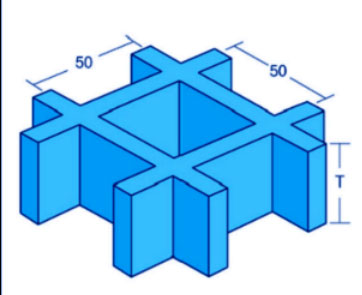

50*50*15 | 50*50 | 15 | 6.0/5.0 |

1220*3660 1220*2440 |

6 | 82 |

| 50*50*25 | 50*50 | 25 | 7.0/5.0 |

1220*3660 1220*2440 |

11 | 78 | |

| 50*50*50 | 50*50 | 50 | 7.5/5.0 |

1220*3660 1220*2440 |

22.5 | 75 | |

|

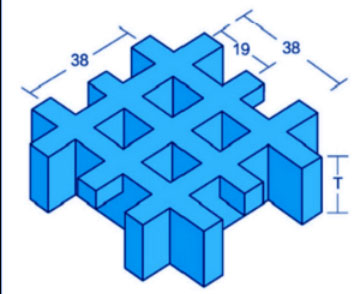

19*19*25 |

19*19 38*38 |

25 | 6.5/5.0 |

1220*3660 1220*2440 |

16.8 | 30 |

| 19*19*30 |

19*19 38*38 |

30 | 6.5/5.0 |

1220*3660 1220*2440 |

19.1 | 30 | |

| 19*19*38 |

19*19 38*38 |

38 | 6.5/5.0 |

1220*3660 1220*2440 |

24 | 30 | |

|

20*20*30 |

20*20 40*40 |

30 | 7.0/5.0 |

1007*3007 |

18.3 | 30 |

| 20*20*38 |

20*20 40*40 |

38 | 7.0/5.0 |

1247*3687 1007*3007 |

22.8 | 42 | |

| 20*20*40 |

20*20 40*40 |

40 | 7.0/5.0 |

1007*3007 |

23.7 | 42 |

Lightweight Yet Strong – Easier to handle and install compared to steel or concrete alternatives.

High Corrosion Resistance – Perfect for chemical plants, wastewater facilities, and coastal areas where exposure to moisture and harsh chemicals is common.

Non-Conductive & Electrically Safe – Ideal for power plants and substations, reducing the risk of electric shocks.

Anti-Slip Surface – Provides enhanced safety for pedestrians and workers, even in wet or oily conditions.

High Load Capacity – Engineered to withstand vehicle and pedestrian traffic, making them suitable for industrial and heavy-duty environments.

Low Maintenance – No need for frequent repainting or anti-corrosion treatments like steel covers.

Industrial Facilities – Chemical plants, power plants, and manufacturing units.

Public Infrastructure – Roads, sidewalks, and pedestrian walkways.

Utility & Drainage Systems – Cable management, water treatment plants, and drainage systems.

Railway & Airport Facilities – Providing safe and durable trench coverage in high-traffic areas.

Solar Panel Mounting Systems – Provide a safe, durable, and easy-to-maintain solution for accessing solar panels installed on rooftops.

To provide you with an accurate quotation, please share the following details:

1.Size & Dimensions – Length, width, thickness, and load-bearing requirements.

2.Surface Finish – Standard anti-slip, grit-coated, or customized finishes.

3.Load Capacity Requirements – Pedestrian, light vehicle, or heavy-duty usage.

4.Environmental Conditions – Indoor, outdoor, high-corrosion, or chemical exposure.

5.Quantity – Required order volume for bulk pricing and lead time estimation.

6.Customization Needs – Specific colors, logo printing, or additional features.

Contact us today for a customized quote! Our team will analyze your requirements and provide you with a tailored quote based on your needs.

Q1: How do Fiberglass Trench Covers compare to steel or concrete covers?

A1: Fiberglass covers are lighter, corrosion-resistant, and non-conductive, making them safer and easier to handle than steel or concrete covers. They also require minimal maintenance, providing long-term cost savings.