Production Discription

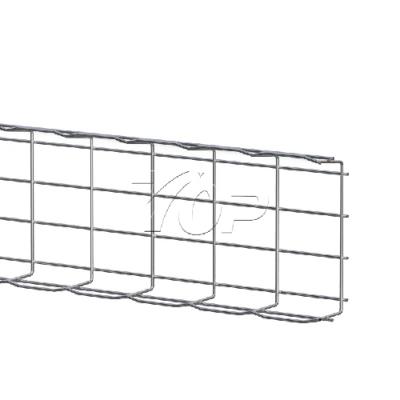

Mesh cable tray made of steel wire. It takes shape after being welded and then undergoes surface treatment. The surface treatment methods are as follows: electro-galvanized (suitable for indoor installation); hot-dip galvanized (with the zinc coating thickness ranging from 60 to 80 micrometers); stainless steel (grade 304),coated plastic etc.

The wire mesh cable tray, because open structure, provides a safe, flexible and effective cable management solution and has a wide range of applications. It is mainly used for the indoor and outdoor overhead laying of power cables with a voltage below 10 kilovolts, pv cables, control cables, lighting wiring, and postal and communication cables. It can be widely applied in industrial plants, pv roof projects, airports, office buildings, apartments, exhibition halls, hotels, large shopping malls, underground parking lots, and residential electrical rooms, etc.

IPv6 network supported

IPv6 network supported