The hot-dip galvanized ground mounting system is a robust, cost-effective, and long-lasting solution for utility-scale solar projects. Its corrosion resistance, high structural integrity, and customizable design make it an ideal choice for diverse environmental conditions.

Material:

Hot Dipped GalvanizedSnow Load:

1.4KN/㎡Wind Load:

60m/sWarranty:

10 YearsService Life:

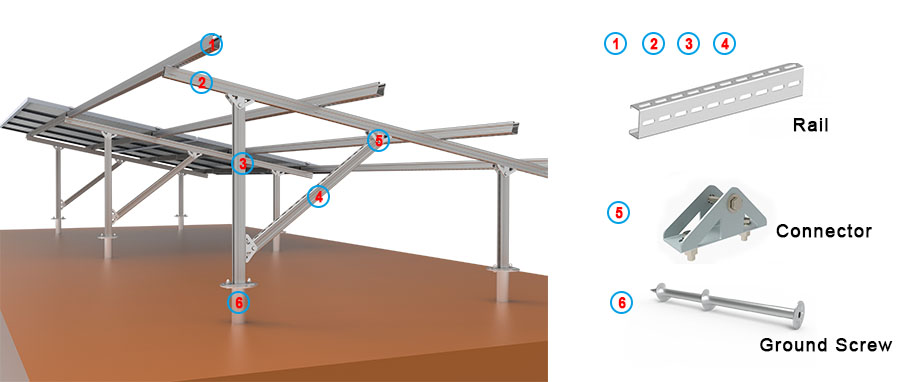

More than 20 YearsThe Hot-Dip Galvanized Ground Mounting System is a durable and corrosion-resistant solar racking solution designed for large-scale ground-mounted solar farms. Made from Q235B or high-strength steel, this mounting system undergoes hot-dip galvanization, ensuring superior resistance against harsh environmental conditions, including desert, coastal, and high-humidity areas.

This high-strength ground mount structure is engineered to support various soil types, including sandy, rocky, and clay-rich terrains. The system is compatible with both fixed-tilt and adjustable-angle installations, allowing optimal solar energy capture.

Hot-Dip Galvanized Steel: Provides exceptional corrosion resistance, ensuring long-term durability.

High Load Capacity: Designed to withstand heavy snow loads, high winds, and extreme weather conditions.

Versatile Ground Anchoring: Compatible with ground screws, concrete foundations, and pile-driven installations.

Customizable Design: Adjustable tilt angles to maximize energy generation based on geographic location.

Quick Installation: Pre-assembled components minimize on-site labor and construction time.

Low Maintenance: The galvanized coating provides long-term protection, reducing maintenance costs.

· Large-scale solar power plants

· Utility-scale and commercial PV projects

· Agricultural solar farms

· Harsh environmental conditions (deserts, coastal regions, high-wind areas)

When requesting a quotation for a hot-dip galvanized ground mounting system, please provide the following details:

Project Location – Helps determine wind load, snow load, and corrosion resistance requirements.

Solar Panel Type & Dimensions – To ensure compatibility with the racking system.

Installation Site Details – Soil type (rocky, sandy, clay), topography, and foundation preference (ground screw, concrete, or pile-driven).

Tilt Angle Requirements – Fixed or adjustable angle for optimal sun exposure.

Row & Array Configuration – To optimize land utilization and energy output.

Load Requirements – Wind speed, snow load, and structural strength specifications.

Project Scale – Total system capacity (MW/kW) and required material volume.

Budget & Timeline – Expected delivery time and cost considerations.

A1:Hot-dip galvanization provides a thick, corrosion-resistant zinc coating that protects the steel from rust, oxidation, and environmental damage, ensuring a lifespan of over 25 years in harsh conditions.

A2:The mounting system is engineered to withstand high wind speeds (up to 50m/s) and heavy snow loads (up to 1.4kN/m²), making it ideal for deserts, coastal areas, and regions with extreme climates.

A3:Our hot-dip galvanized ground mount system supports,Ground screws (for quick and flexible installation)

A4:Yes, we offer both fixed-tilt and adjustable-angle designs, with tilting options between 5° and 45°, depending on your location and energy yield optimization needs.

A5:We primarily use Q235B high-strength carbon steel or Q355B steel for enhanced durability and load capacity.

A6:Installation time depends on project size and ground conditions. However, thanks to our pre-assembled components, installation can be completed 40% faster compared to conventional systems.

· Aluminum systems are lighter but more suitable for small-scale or rooftop applications.