Selecting the right solar panel clamps is crucial for ensuring the stability, durability, and efficiency of a solar mounting system. Whether for roof-mounted or ground-mounted solar installations, the clamps play a vital role in securing solar panels and withstanding various environmental conditions such as strong winds, heavy snow loads, and temperature fluctuations.

With a wide range of solar panel clamps available in the market, how do you determine the best one for your project? In this article, we’ll explore the different types of clamps, key selection factors, and best industry practices to help you make an informed decision.

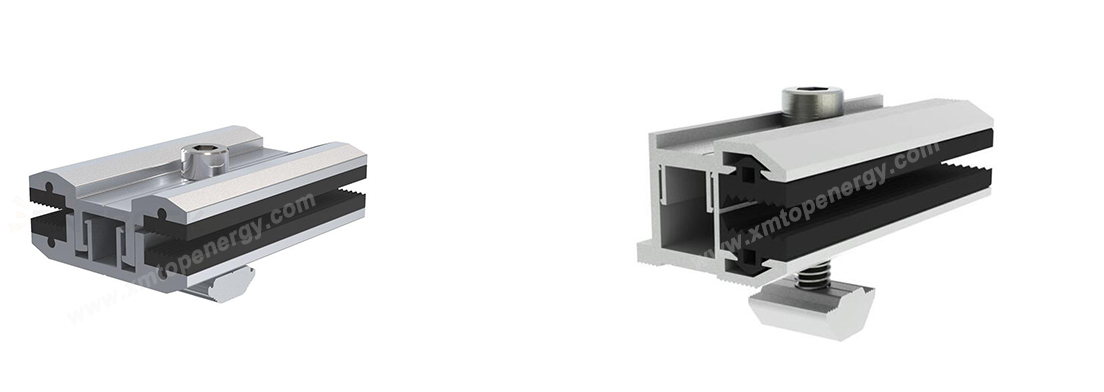

Solar panel clamps are generally categorized into mid clamps and end clamps, each serving a specific purpose in securing the solar modules.

· Used to connect two adjacent solar panels in a row.

· Provides uniform spacing and structural integrity.

· Typically made from high-strength aluminum or stainless steel for corrosion resistance.

· Installed at the edges of the solar array to secure the outermost panels.

· Ensures the panels remain fixed even in harsh weather conditions.

· Available in different sizes and designs to fit various panel thicknesses.

Additionally, specialized clamps such as railless clamps, adjustable clamps, and frameless panel clamps are also available for unique installation requirements.

Not all clamps fit every solar panel type. It’s important to check:

· Panel thickness – Ensure the clamp matches the dimensions of your solar module.

· Framed vs. Frameless panels – Some clamps are designed exclusively for frameless glass panels, while others work with standard framed modules.

High-quality solar clamps are made from anti-corrosive materials to withstand outdoor exposure for decades. Common materials include:

· Aluminum Alloy (6063-T5, 6005-T5) – Lightweight, corrosion-resistant, and high-strength.

· Stainless Steel (SUS 304, SUS 316) – Excellent durability, commonly used in harsh weather conditions.

Solar clamps must be able to withstand wind loads, snow loads, and thermal expansion. Ensure that the clamps are tested and certified to meet industry standards such as ISO, CE, and UL certifications.

Time and labor costs can be reduced by selecting clamps with:

· Pre-assembled components for quick installation.

· Tool-free locking mechanisms that simplify the mounting process.

· Adjustable designs that fit multiple panel sizes.

Different solar mounting systems require specific clamp designs, including:

· Rail-based mounting systems – Clamps are attached to rails that hold the solar panels.

· Railless mounting systems – Clamps attach directly to the roof, reducing installation components.

· Ground-mounted structures – Heavy-duty clamps designed for stability in open-field installations.

Ensure the clamps comply with international quality and safety standards, including:

· TÜV Rheinland certification for quality assurance.

· ISO 9001 certification for manufacturing excellence.

· ASTM and UL standards for mechanical integrity.

Choose adjustable clamps if your project involves panels of different thicknesses.

Opt for stainless steel fasteners to prevent corrosion over time.

Verify that the clamps are tested for wind and snow loads specific to your region.

Ensure proper torque settings during installation to avoid panel damage.

Work with trusted solar racking manufacturers to get high-quality clamps with warranties.

Choosing the right solar panel clamps is a crucial step in ensuring a secure, durable, and cost-effective solar installation. By considering compatibility, material quality, load resistance, and ease of installation, you can select the best clamps for your project.

For businesses and installers, investing in high-quality, certified solar clamps not only enhances system longevity but also boosts customer satisfaction. Make sure to source clamps from reliable manufacturers to guarantee optimal performance for your solar mounting system.

Xiamen TopFence Co.,Ltd.

Xiamen TopFence Co.,Ltd. No. 77, LingXia South Road, Huli District, Xiamen City, Fujian, China

No. 77, LingXia South Road, Huli District, Xiamen City, Fujian, China Tel: +8613365923720

Tel: +8613365923720

Email: info@xmtopfence.com

Email: info@xmtopfence.com

IPv6 network supported Sitemap

| XML

| Blog

| Privacy Policy

IPv6 network supported Sitemap

| XML

| Blog

| Privacy Policy